IT infrastructure for the smart factory

Digital transformation in industry

29 June 2022

At the end of May the Hannover Trade Fair once again opened its doors after an interval of two years due to the pandemic. Caught between climate change, disrupted supply chains and rising energy prices, the leading industrial fair focussed on intelligent and CO2-reducing production processes. It became clear that the smart factory with AI, real time, 5G and Industry 4.0 applications is still a pipe dream in most manufacturing enterprises. The potential for digitisation is nowhere near being fully exploited.

This is also attested by the PwC Study “Digital Factory Transformation Survey 2022”. Although worldwide industrial enterprises invest more than one trillion euros in building smart factories, two thirds of the 700 companies surveyed are still only beginning to implement digital systems and technologies. After a period of learning, the transformation in many industrial enterprises is only really starting to happen now.

AI, 5G, IoT and edge computing become practicable

The German Engineering Federation (VDMA) appropriately announced the good news that many of its member companies have already developed solutions for the major task of industrial transformation. They range from the use of AI in research through employment of a digital twin for sustainable climate-neutral production to cloud-based business models.

The most important thing for industry is that 5G simplifies challenging machine-to-machine communication (M2M) for Industry 4.0. Industrial 5G enables many professional applications relating to the wireless networking of devices, vehicles and machines (IoT devices). Not only are campus networks for edge computing extremely performant with or without a connection to the public mobile communications network, but they also comply with the most stringent data security requirements.

Industrial transformation succeeds with modern IT infrastructure

The aforementioned smart technologies for future production bring new challenges which traditional IT infrastructures are no longer able to meet. All those wanting to address industrial transformation actively as well as reactively must therefore address fundamental issues such as high-performance networking and the requisite local computing power.

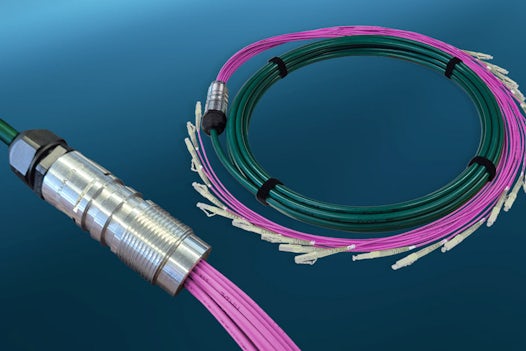

The rapid progress of digitisation compels companies to set up an agile, adaptable and high-powered IT environment. A well thought-out IT infrastructure coupled with expert advice is an important part of the solution. In its portfolio Datwyler IT Infra has a wide selection of future-proof products for the digital factory. With the development of private 5G networks in collaboration with Nokia, with edge computing applications and successfully implemented AI projects Datwyler shows that future technologies have long been everyday practice.